When it comes to construction and fabrication, few materials are as underrated yet essential as angle bars (also known as angle iron). Whether you’re putting up a commercial building, reinforcing a frame, or crafting a DIY shelving unit, angle bars prove time and again why it’s one of the most trusted steel products in the world.

Strength That Holds It All Together

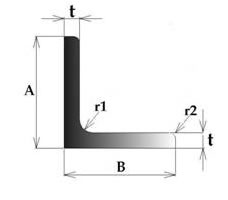

The defining characteristic of angle bars is its incredible strength. With its L-shaped cross-section, angle bars are designed to resist bending under pressure, making it capable of supporting substantial weight. This makes it a natural choice for structural applications, from large-scale building frameworks to load-bearing supports in smaller projects. When stability and safety are non-negotiable, angle iron stands as a reliable backbone.

Versatility Across Projects

Another advantage is versatility. Available in different sizes, thicknesses, and finishes, angle bars adapt to both heavy-duty construction projects and smaller, creative builds. Architects use it to frame staircases and bridges, while DIY enthusiasts turn it into tables, racks, and garden structures. Whether it’s skyscrapers or backyard furniture, angle iron offers a balance of strength and flexibility that few materials can match.

Ease of Use for Custom Solutions

Unlike materials that require specialized tools or expertise, angle bars are refreshingly easy to work with. It can be cut with basic tools, drilled for bolts, or welded for permanent fixtures. This makes it simple to customize, ensuring that the material fits your exact design or structural needs. For contractors, this means faster project completion. For DIY builders, it means endless possibilities without excessive hassle.

Durability Indoors and Out

Finally, angle bars deliver exceptional durability. Naturally resilient and even more reliable when coated or painted, it resists rust and corrosion—critical for projects exposed to the elements. This makes it equally suitable for indoor installations and outdoor frameworks. With proper care, angle iron structures can last for decades, offering unmatched value for money.

In SHORT: If you need a material that combines strength, versatility, ease of use, and long-term durability, angle bars should be at the top of your list. From construction sites to creative DIY spaces, it’s the dependable steel product that proves you don’t need to compromise between power and practicality. And remember to buy quality, buy certified!