In this article by NEDA, they show a 2-storey experimental house with a total floor area of 53 square meters constructed utilizing coconut fiber-cement boards (CFB) together with component steel as its structural framework.

Given the plentiful coconut tree- ubiquitous in fact on our Philippine shores, CFB as an alternative construction material for walling, ceiling, roofing and base support in upper level flooring of house makes complete sense. In fact, NEDA proposes its use in the fabrication of furniture (tables, chairs, desks, etc.), cabinets, boxes and vases inside the house.

Roofing System

MATERIALS USED: The house has an A-frame design with the roof system consisting of the traditional rafters and purlins construction. In the picture, the green roof cover is made of 8 mm thick, 75 cm wide, and 75 cm long CFB panels painted with waterproof paints.

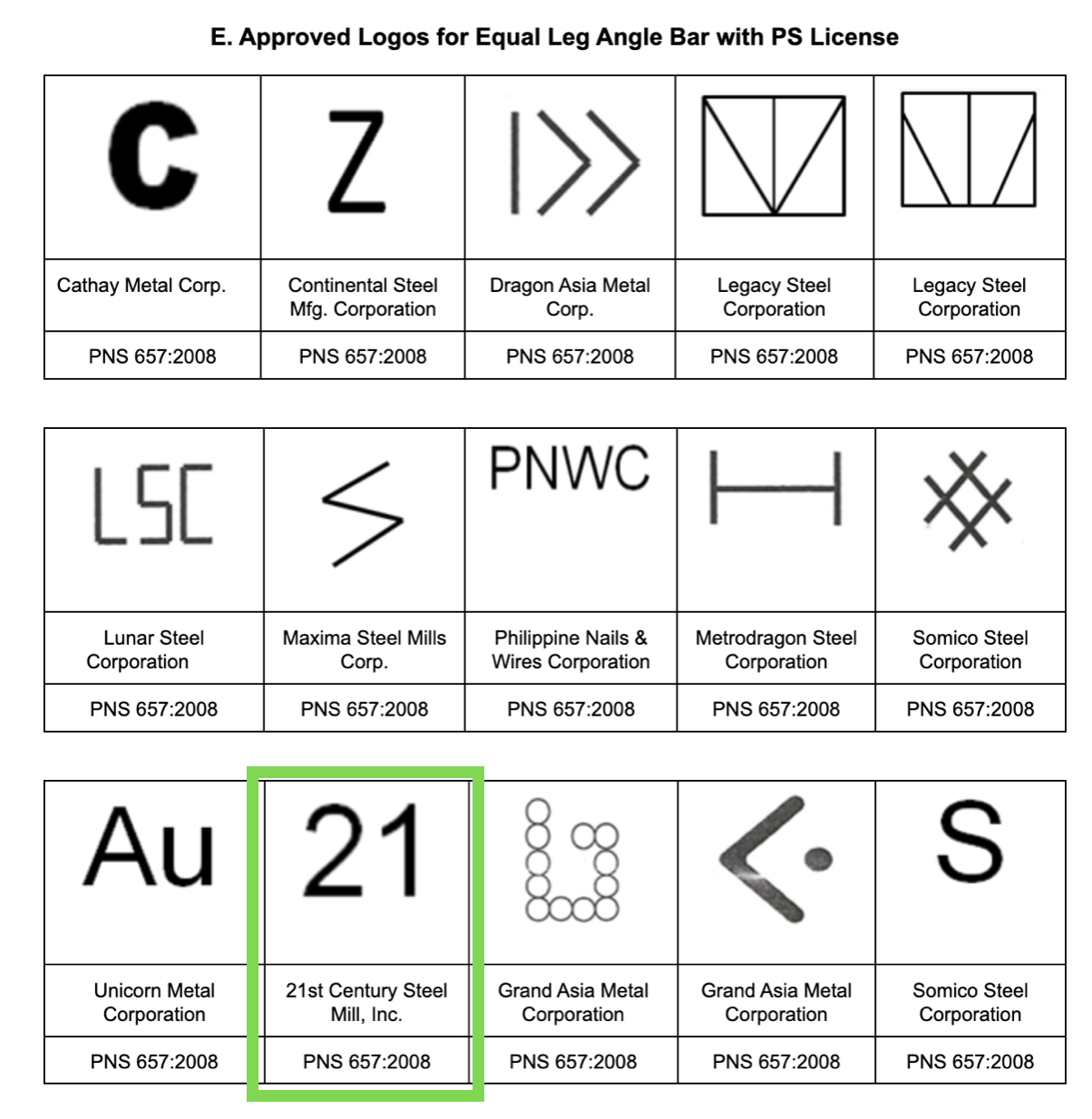

The rafters consist of 0.6 cm X 5 cm x 5 cm angular steel bars and the purlins made of 0.60 cm x 3.8 cm x 75 cm channel bars. The components were assembled on site by welding the members together. The two opposite rafters were joined together end to end at the ridge beam (0.60 cm x 5 cm x 5 cm angular steel bar) while the other ends were directly connected to the base plate of the second level floor extending to the eaves or overhang of about one (1) meter.

Interestingly, the main roof structure was made to incline by about 40% greater than the normal slope of 35 degrees considering that the roof cover is made of experimental fiber-cement boards. This will ensure faster surface water run-off in case of downpour.

Of course, the question is, how strong and lasting is the coconut fiber? This project by NEDA aims to evaluate the performance of CFB in actual service condition. To find out more click here

Note: A coconut fiber-cement board (CFB) is a product manufactured from fibrous materials like coconut coir, fronds, spathes and shredded wood that are mixed with Portland cement at a predetermined ratio of 60-70% cement to 30-40% fiber by weight.